Philips 21PV385 Service Manual

Hide thumbs

Also See for 21PV385:

- Specifications (2 pages) ,

- User manual (17 pages) ,

- User manual (17 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

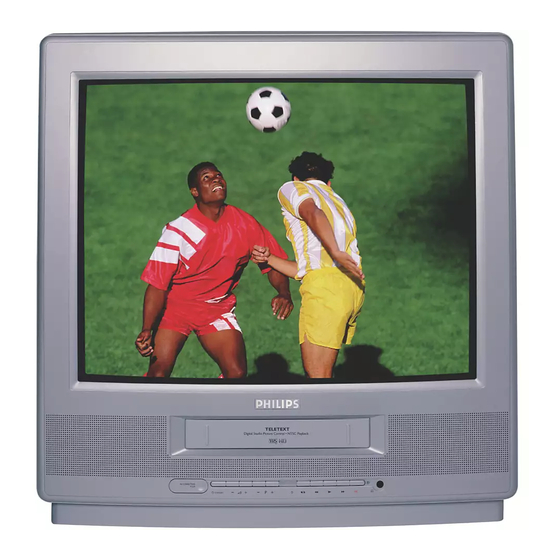

TV-VCR Combination

Service

Service

Service

Service Manual

Contents

Chapter

Sec. 1:

Adjustment Procedure

Schematic Diagrams and CBA's

Exploded Views

Mechanical and Electrical Parts Lists

Sec. 2: Standard Maintenance

Mechanism Alignment Procedures

Disassembly / Assembly of Mechanism

Deck Exploded Views

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified

be used.

Published by BK 2004 Video Service Department Printed in the Netherlands c Copyright reserved Subject to modification

21PV385

Survey of versions:

/01

PAL-BG, EURO

/07

PAL I, UK/IRELAND

/39

PAL/SECAM-BG+PAL/SECAM-L/L',FRANCE

/58

PAL-BG/DK+SECAM-BG/DK,EAST-EURO

/01/07/39/58

VN: 1B

GB

3103 785 22330

Advertisement

Chapters

Table of Contents

Summary of Contents for Philips 21PV385

- Page 1 TV-VCR Combination Service 21PV385 /01/07/39/58 Service Service Service Manual Contents VN: 1B Survey of versions: PAL-BG, EURO Chapter PAL I, UK/IRELAND PAL/SECAM-BG+PAL/SECAM-L/L',FRANCE Sec. 1: Adjustment Procedure PAL-BG/DK+SECAM-BG/DK,EAST-EURO Schematic Diagrams and CBA's Exploded Views Mechanical and Electrical Parts Lists Sec. 2: Standard Maintenance...

-

Page 2: Table Of Contents

MAIN SECTION TV-VCR COMBINATION Sec. 1: Main Section I Adjustment Procedures I Schematic Diagrams and CBA’s I Exploded Views I Mechanical and Electrical Parts List TABLE OF CONTENTS IMPORTANT SAFETY PRECAUTIONS ............1-1-1 STANDARD NOTES FOR SERVICING . -

Page 3: Important Safety Precautions

IMPORTANT SAFETY PRECAUTIONS Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally important to implement the following precautions when a set is being serviced. - Page 4 ing is performed that involves B+, horizontal de- earth ground. If a voltage reading in excess of 1.0V flection or high voltage. Correct operation of the is obtained, remove and reinsert the AC power X-radiation protection circuits also must be recon- plug in the opposite polarity and again measure firmed each time they are serviced.

- Page 5 Precautions during Servicing H. When a power cord has been replaced, check that 5~6 kg of force in any direction will not loosen it. A. Parts identified by the ( ! ) symbol are critical for I. Also check areas surrounding repaired locations. safety.

- Page 6 Safety Check after Servicing Examine the area surrounding the repaired location for Chassis or Secondary Conductor damage or deterioration. Observe that screws, parts and wires have been returned to original positions. Afterwards, perform the following tests and confirm the Primary Circuit Terminals specified values in order to verify compliance with safety standards.

-

Page 7: Standard Notes For Servicing

STANDARD NOTES FOR SERVICING Circuit Board Indications How to Read the Values of the Rect- angular Type Chip Components 1. The output pin of the 3 pin Regulator ICs is indi- cated as shown: Example: (a) Resistor Top View Bottom View Input = 473 = 47 [kΩ] 2. - Page 8 1.2. Standard solder a. Soldering Iron Soldering Iron Use a pencil-type soldering iron (less than 30 Tweezers watts). Solder b. Solder Eutectic solder (Tin 63%, Lead 37%) is recom- mended. c. Soldering time Do not apply heat for more than 4 seconds. d.

- Page 9 b. Affix the wire to a workbench or solid mounting point, as shown in Fig. S-1-5. Desoldering Braid c. Pull up on the wire as the solder melts so as to lift Flat Pack-IC the IC leads from the CBA contact pads, while heating the pins using a fine tip soldering iron or hot air blower.

- Page 10 <Correct> Presolder Grounding Band 1MΩ Flat Pack-IC 1MΩ Conductive Sheet or Copper Plate Fig. S-1-7 Instructions for Handling Semiconductors Electrostatic breakdown of the semiconductors may occur due to a potential difference caused by electro- static charge during unpacking or repair work. Ground for Human Body Be sure to wear a grounding band (1MΩ) that is prop- erly grounded to remove any static electricity that may...

-

Page 11: Preparation For Servicing

PREPARATION FOR SERVICING How to Enter the Service Mode Adjustment Mode No need to use. Caution: 1 No need to use. 1. Optical sensors system are used for Tape Start and H. Shift adjustment mode: See adjust- End Sensor on this equipment. Read this page ment instructions page 1-6-5. -

Page 12: Operating Controls And Functions

To switch off or on, interrupt menu function. 0..9 Press to select channels at TVCR. SLEEP To select the switch-off time in 30 minutes intervals. SYSTEM To change Video (colour) system. (21PV385/39, 58) SLEEP SYSTEM Doesn’t work on these models. (21PV385/01, 07) STATUS/EXIT PLAY... - Page 13 Front of your TVCR VIDEO AUDIO STANDBY/ON STANDBY/ON: To switch off or on, interrupt menu function. – Volume: In connection with the button to adjust the volume. Programme number: To select the programme number. During playback, press to adjust the track- To remove vertical jitter in a Still picture.

-

Page 14: Cabinet Disassembly Instructions

CABINET DISASSEMBLY INSTRUCTIONS 1. Disassembly Flowchart REMOVAL REMOVE/ This flowchart indicates the disassembly steps for the *UNHOOK/ cabinet parts, and the CBA in order to gain access to LOC. PART Fig. UNLOCK/RELEASE/ Note item(s) to be serviced. When reassembling, follow the UNPLUG/ steps in reverse order. - Page 15 5. Removal of the Top Cover. 8. Removal of the Text CBA. Remove five screws (S-4) and CL604, and remove Remove a screw (S-9) and Text Holder, and dis- the Top Shield. connect connectors CN751 and CN752. Then, lift the Text CBA up. 6.

- Page 16 [4] Tray Chassis Unit CL604 [6] Top Cover [2] Power Unit and [8] Deck Unit Tray Chassis Unit [9] Text CBA S-10 S-10 S-10 Text Holder S-10 [10] Main CBA Power Knob [5] H.V./Power Supply CBA [7] Bottom Plate [3] Power Unit Fig.

- Page 17 S-11 Anode Cap CRT CBA S-11 S-11 [11] CRT S-11 Fig. 4 1-5-4 T6552DC...

- Page 18 CRT CBA ANODE CN501B FOCUS SCREEN CN501 CN502 H.V./POWER SUPPLY CBA CN552 CL501A CN551 CN602 CN601 TO DEGAUSS COIL MAIN CBA CL403 TEXT CBA CL302A CL401 CL301A CL402 CN751 CN752 CN201 CN151 CL603A CAPSTAN TO SPEAKER MOTOR CL604 TO TOP COVER CYLINDER ASSEMBLY ACE HEAD...

-

Page 19: Electrical Adjustment Instructions

It is important to perform these adjustments only Model Option Code after all repairs and replacements have been com- pleted. 21PV385/07 0176 Also, do not attempt these adjustments unless the 21PV385/01 0178 proper equipment is available. - Page 20 1. DC114V (+B) Adjustment 2. H Adjustment Purpose: To obtain correct operation. Purpose: To get correct horizontal position and size of screen image. Symptom of Misadjustment: The picture is dark and unit does not operate correctly. Symptom of Misadjustment: Horizontal position and size of screen image may not be properly displayed.

- Page 21 3. C-Trap Adjustment 4. To enter the DSPC mode, press [1] button on the remote control unit. Recording starts automatically Purpose: To get minimum leakage of the color signal and “DSPC” appears on the display. carrier. TVCR Symptom of Misadjustment: If C-Trap Adjustment is incorrect, stripes will appear on the screen.

- Page 22 5. SECAM Black Level Adjustment 6. V. Size Adjustment Purpose: To set Black Level of the SECAM signal R- Purpose: To obtain correct vertical height of screen Y/B-Y to Ref. level. image. Symptom of Misadjustment: If Black Level of the Symptom of Misadjustment: If V.

- Page 23 8. H. Shift Adjustment 8. To enter the CUT OFF (G) mode, press [2] button on the remote control unit. Purpose: To obtain correct horizontal position and 9. Press the [P+/P-] buttons until the horizontal line size of screen image. becomes white.

- Page 24 10. White Balance Adjustment 11. Sub-Brightness Adjustment Purpose: To get proper brightness. Purpose: To mix red, green and blue beams correctly Symptom of Misadjustment: If Sub-Brightness is for pure white. incorrect, proper brightness cannot be obtained by Symptom of Misadjustment: White becomes bluish adjusting the Brightness Control.

- Page 25 12. Setting for CONTRAST, 13. Focus Adjustment COLOR, TINT and SHARP Purpose: Set the optimum Focus. Data Values Symptom of Misadjustment: If Focus Adjustment is incorrect, blurred images are shown on the display. General 1. Enter the Service mode. (See page 1-6-10) Test point Adj.

- Page 26 14. Head Switching Position Adjustment Purpose: Determine the Head Switching Position dur- ing Playback. Symptom of Misadjustment: May cause Head Switching Noise or Vertical Jitter in the picture. Note: Unit reads Head Switching Position automati- cally and displays it on the screen (Upper Left Corner). Manual Adjustment 1.

- Page 27 Adjustment Points and Test Points H.V./Power Supply CBA Top View Focus-control (Upper side) Screen-control (Lower side) R590 (H Adjustment) TP503 VR601 TP504 +B ADJ Main CBA Top View TP007 N-A-PB J361G4 TP002 (SECAM RF-SW Black Level TP001 Adjustment) TP008 C-PB J349F3 TP003 B-OUT...

-

Page 28: Block Diagrams

BLOCK DIAGRAMS Servo/System Control Block Diagram T6552BLS 1-7-1... - Page 29 Video Block Diagram T6552BLV 1-7-2...

- Page 30 Audio Block Diagram T6552BLA 1-7-3...

- Page 31 TV Block Diagram T6552BLT 1-7-4...

- Page 32 CRT/H.V. Block Diagram T6552BLCRT 1-7-5...

- Page 33 Power Supply Block Diagram T6552BLP 1-7-6...

- Page 34 MECHANICAL TROUBLE INDICATOR 1, Each Malfunction Indication POWER SAFETY 1) POWER SAFETY 1 If the MONITOR is turned ON right after the Mechani- If P-SAFETY 1 port becomes continuously 2.5V or cal Malfunction occurs or POWER SAFETY/X-RAY is less for 120 msec. (4 times 40 msec. interval) when turned ON, display the following character to show MONITOR is ON, the unit shall be assumed to be Malfunction after the EJECT display.

- Page 35 Mechanical Malfunction determination 4) Countermeasure for CASSETTE LOADING Mal- function 1) REEL Malfunction detection a) CASSETTE IN operating Malfunction Countermeasure for REEL and CAPSTAN motor If LD-SW does not go to SB position after a lapse rotation malfunction (Except CASSETTE LOAD- of 5 sec.

-

Page 36: Schematic Diagrams / Cba's And Test Points

SCHEMATIC DIAGRAMS / CBA'S AND TEST POINTS Standard Notes Notes: WARNING 1. Do not use the part number shown on these draw- ings for ordering. The correct part number is Many electrical and mechanical parts in this chassis shown in the parts list, and may be slightly different have special characteristics. - Page 37 Main 1/5 Schematic Diagram Parts Location Guide Ref No. Position Ref No. Position Ref No. Position Ref No. Position CAPACITORS CONNECTOR RESISTORS RESISTORS C203 CN201 R220 R268 DIODES C205 R221 R269 C207 D201 R222 R270 C208 D202 R223 R271 C209 D204 R224 R272...

- Page 38 Schematic Diagrams are as shown below: Models and Marks PLAY MODE MODEL MARK REC MODE (2.5) “ “ = SMD 21PV385/07 THE SAME VOLTAGE FOR INDICATES THAT THE VOLTAGE 21PV385/01 BOTH PLAY & REC MODES. IS NOT CONSISTENT HERE. 21PV385/58 21PV385/39 1-8-3...

- Page 39 Main 2/5 Schematic Diagram Voltage indications for PLAY and REC modes on the Schematic Diagrams are as shown below: PLAY MODE REC MODE “ “ = SMD (2.5) THE SAME VOLTAGE FOR INDICATES THAT THE VOLTAGE BOTH PLAY & REC MODES. IS NOT CONSISTENT HERE.

- Page 40 Main 2/5 Schematic Diagram Parts Location Guide Ref No. Position Ref No. Position Ref No. Position Ref No. Position CAPACITORS CAPACITORS TRANSISTORS RESISTORS C401 C445 Q401 R861 C402 C452 Q851 R862 C403 C851 Q852 R863 C404 C855 Q853 R864 C405 C856 Q854 R865...

- Page 41 Main 3/5 Schematic Diagram Parts Location Guide Ref No. Position Ref No. Position Ref No. Position CAPACITORS CAPACITORS RESISTORS C001 C332 R156 C002 C333 R157 C006 C334 R301 C008 C336 R302 C009 C338 R303 C151 C340 R304 C152 C341 R305 C154 C344 R306...

- Page 42 Main 3/5 Schematic Diagram Voltage indications for PLAY and REC modes on the Schematic Diagrams are as shown below: PLAY MODE REC MODE “ “ = SMD (2.5) THE SAME VOLTAGE FOR INDICATES THAT THE VOLTAGE BOTH PLAY & REC MODES. IS NOT CONSISTENT HERE.

- Page 43 “ = SMD Q681 THE SAME VOLTAGE FOR INDICATES THAT THE VOLTAGE Q682 BOTH PLAY & REC MODES. IS NOT CONSISTENT HERE. Q683 Q684 Q685 Q686 Comparison Chart of Models and Marks MODEL MARK 21PV385/07 21PV385/01 21PV385/58 21PV385/39 1-8-11 1-8-12 T6552SCM4...

- Page 44 Main 4/5 Schematic Diagram Parts Location Guide Ref No. Position Ref No. Position CAPACITORS DIODES C471 D691 C472 D694 C473 D695 C474 D696 C475 D697 C476 C478 IC471 C479 IC681 COILS C480 C481 L681 C483 L682 TRANSISTORS C484 C485 Q682 C486 Q684 C681...

- Page 45 Main 5/5 Schematic Diagram Parts Location Guide Ref No. Position Ref No. Position CAPACITORS RESISTORS BB-2 CC-4 C703 R703 BB-4 CC-4 C707 R704 BB-4 BB-4 C708 R707 BB-4 CC-4 C709 R709 CC-4 BB-4 C710 R710 CC-3 AA-3 C711 R711 CC-3 CC-4 C713 R712...

- Page 46 Main 5/5 Schematic Diagram Voltage indications for PLAY and REC modes on the Schematic Diagrams are as shown below: PLAY MODE “ “ = SMD REC MODE (2.5) THE SAME VOLTAGE FOR INDICATES THAT THE VOLTAGE BOTH PLAY & REC MODES. IS NOT CONSISTENT HERE.

- Page 47 Main CBA Parts Location Guide Ref No. Position Ref No. Position Ref No. Position Ref No. Position Ref No. Position Ref No. Position Ref No. Position Ref No. Position Ref No. Position Ref No. Position CAPACITORS CAPACITORS CAPACITORS CAPACITORS DIODES TRANSISTORS RESISTORS RESISTORS...

- Page 48 Main CBA Top View Sensor CBA Top View BHF300F01011-A TO SENSOR CBA (END-SENSOR) BHF300F01011-B J361G4 (SECAM Black Level Adjustment) TP007 N-A-PB TP002 RF-SW TP001 TP008 C-PB J349F3 (C-Trap Adjustment) TP003 V-OUT TO SENSOR CBA (START-SENSOR) 1-8-19 1-8-20 BT6600F01012...

- Page 49 Main CBA Bottom View PIN 8 PIN 29 PIN 48 OF IC401 OF IC401 OF IC401 WF17 PIN 58 OF IC201 WF18 PIN 59 OF IC201 PIN 52 OF IC301 WF11 PIN 7 OF IC301 WF10 PIN 13 OF IC301 1-8-21 1-8-22 BT6600F01012...

- Page 50 CRT Schematic Diagram Voltage indications for PLAY and REC modes on the Schematic Diagrams are as shown below: PLAY MODE REC MODE (2.5) THE SAME VOLTAGE FOR INDICATES THAT THE VOLTAGE BOTH PLAY & REC MODES. IS NOT CONSISTENT HERE. CRT SCHEMATIC DIAGRAM PARTS LOCATION GUIDE Ref No.

- Page 51 CRT CBA Top View H.V./Power Supply 1/2 Schematic Diagram Parts Location Guide Ref No. Position Ref No. Position Ref No. Position CAPACITORS DIODES RESISTORS C602 D630 R632 CRT CBA PARTS LOCATION GUIDE C604 D631 R633 Ref No. Position C611 D634 R634 C613 D635...

- Page 52 H.V./Power Supply 1/2 Schematic Diagram CAUTION ! Voltage indications for PLAY and REC modes on Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit. the Schematic Diagrams are as shown below: If Main Fuse (F601) is blown, check to see that all components in the power supply circuit are not defective before you connect the AC plug to the AC power supply.

- Page 53 H.V./Power Supply 2/2 Schematic Diagram H.V./POWER SUPPLY 2/2 SCHEMATIC DIAGRAM PARTS LOCATION GUIDE Ref No. Position Ref No. Position Ref No. Position Ref No. Position Ref No. Position Ref No. Position Ref No. Position CAPACITORS CAPACITORS DIODES RESISTORS RESISTORS RESISTORS MISCELLANEOUS R550 C551...

- Page 54 H.V./Power Supply CBA Top View CAUTION ! CAUTION BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit. FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, SUPPLY CIRCUIT, AN ISOLATION TRANSFORMER MUST BE USED.

- Page 55 H.V./Power Supply CBA Bottom View CAUTION ! CAUTION BECAUSE A HOT CHASSIS GROUND IS PRESENT IN THE POWER Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit. FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, SUPPLY CIRCUIT, AN ISOLATION TRANSFORMER MUST BE USED.

- Page 56 Junction-A CBA Top View Junction-A CBA Bottom View H.V./Power Supply CBA Parts Location Guide Ref No. Position Ref No. Position Ref No. Position Ref No. Position CAPACITORS DIODES RESISTORS RESISTORS C551 D601 R553 R628 C552 D602 R554 R629 C553 D603 R555 R631 C554...

- Page 57 Text Schematic Diagram Voltage indications for PLAY and REC modes on the Schematic Diagrams are as shown below: TEXT SCHEMATIC DIAGRAM PARTS LOCATION GUIDE PLAY MODE Ref No. Position REC MODE (2.5) CAPACITORS THE SAME VOLTAGE FOR INDICATES THAT THE VOLTAGE C901 BOTH PLAY &...

- Page 58 Text CBA Top View Text CBA Bottom View TEXT CBA PARTS LOCATION GUIDE Ref No. Position Ref No. Position Ref No. Position Ref No. Position Ref No. Position CAPACITORS CAPACITORS DIODES RESISTORS RESISTORS C901 C926 D908 R903 R919 CONNECTORS C902 D909 R904 R920...

-

Page 59: Waveforms

WAVEFORMS Z13PWF 1-9-1... -

Page 60: Wiring Diagram

WIRING DIAGRAM 1-10-1 T6552WI... -

Page 61: System Control Timing Charts

SYSTEM CONTROL TIMING CHARTS Chart 1 EJECT ST-S "OFF" CASS.LOAD LD-FWD 0.2S LD-REV SFT-SW STOP(B) POWER LD-FWD 0.4S LD-FWD 0.2S LD-REV 0.2S LD-FWD 0.5S LD-REV STOP(A) PLAY LD-FWD PLAY LD-FWD RS1(RS2) LD-REV 0.2S LD-FWD FS1(FS2) PLAY PLAY PAUSE STILL PAUSE NOISE CANCEL PAUSE... - Page 62 Chart 2 STOP(A) STOP LD-REV 0.2S LD-FWD 0.2S STOP /EJECT 1.0S LD-FWD 0.5S LD-REV STOP(A) LD-REV 0.2S LD-FWD 0.2S STOP /EJECT LD-REV 1.0S LD-FWD 0.5S LD-REV STOP(A) LD-FWD PAUSE LD-FWD 2.5S Short REV LD-REV 0.2S LD-FWD REC PAUSE REC or PAUSE STOP /EJECT...

-

Page 63: Ic Pin Function Descriptions

IC PIN FUNCTION DESCRIPTIONS Comparison Chart of Models and Marks Signal Mark Function Name Model Mark Not Used 21PV385/07 21PV385/01 Not Used 21PV385/58 Not Used 21PV385/39 Not Used RAPID-Switch Input IC 201 (TV/VCR Micro Controller) SCART- Signal from Scart MUTE “H”... - Page 64 Signal Signal Mark Function Mark Function Name Name OSDVcc OSDVcc Not Used Not Used Power Voltage OUT TEXT-RESET Tele Text Reset P-DOWN-L Down Detector CV-IN Video Signal Input Signal at Low Not Used H-SYNC H-SYNC Input Capstan Motor C-FG Rotation Detection V-SYNC V-SYNC Input Pulse...

-

Page 65: Lead Identifications

LEAD IDENTIFICATIONS 2SC5885000RF 2SC3619 MID-32A22F 2SK2647 2SD1913(R) TT2140LS-YB11 KTC3503Y PT204-6B-12 KTC2026Y S: Souce E: Emitter D: Drain C: Collector B: Base G: Gate E C B B C E S D G B C E 2SA1015-GR(TPE2) 2SA1346 2SA1175(F) LA78040A 2SC1815-GR(TPE2) 2SA950(Y,O) 2SC2120-O(TPE2) 2SC1627Y-TPE2... -

Page 66: Electrical Parts List

PRODUCT SAFETY NOTE: Products marked with a h have special characteristics important to safety. Before replacing any of these components, read carefully the product safety notice in this service manual. Don’t degrade the safety of the product through improper servicing. NOTES: C…..±0.25% D…..±0.5%... - Page 67 ELECTRICAL PARTS LIST Pos. 12 NC Description C227 CHIP CERAMIC CAP. CH D 10PF/50V C228 CHIP CERAMIC CAP. CH D 10PF/50V C229 CHIP CERAMIC CAP.(MELF) Y K 4700PF/16V C230 CHIP CERAMIC CAP.(1608) F Z 0.1UF/25V C231 CHIP CERAMIC CAP.(MELF) F Z 0.01UF/16V C233 9965 000 09764 CHIP CERAMIC CAP.(MELF) Y K 1000PF/35V C234...

- Page 68 ELECTRICAL PARTS LIST Pos. 12 NC Description C344 CHIP CERAMIC CAP.(MELF) Y K 1000PF/35V C350 ELECTROLYTIC CAP. 220UF/10V M C401 CHIP CERAMIC CAP.(1608) B K 0.01UF/50V C402 ELECTROLYTIC CAP. 1UF/50V M H7 C403 ELECTROLYTIC CAP. 1UF/50V M H7 C404 ELECTROLYTIC CAP. 100UF/6.3V H7 C405 CHIP CERAMIC CAP.(1608) F Z 0.1UF/25V C406...

- Page 69 ELECTRICAL PARTS LIST Pos. 12 NC Description C684 9965 000 23541 CHIP CERAMIC CAP.(MELF) B K 180PF/50V C687 ELECTROLYTIC CAP. 47UF/25V M C688 ELECTROLYTIC CAP. 47UF/25V M C689 ELECTROLYTIC CAP. 470UF/10V M C691 ELECTROLYTIC CAP. 2.2UF/50V M C694 ELECTROLYTIC CAP. 100UF/10V M C703 ELECTROLYTIC CAP.

- Page 70 ELECTRICAL PARTS LIST Pos. 12 NC Description D212 4822 130 32778 SWITCHING DIODE 1SS133(T-77) D213 4822 130 32778 SWITCHING DIODE 1SS133(T-77) D214 4822 130 32778 SWITCHING DIODE 1SS133(T-77) D302 4822 130 32778 SWITCHING DIODE 1SS133(T-77) D303 4822 130 32778 SWITCHING DIODE 1SS133(T-77) D304 4822 130 32778 SWITCHING DIODE 1SS133(T-77) D305...

- Page 71 ELECTRICAL PARTS LIST Pos. 12 NC Description Q205 9965 000 20922 PHOTO TRANSISTOR MID-32A22F Q206 4822 130 10145 RES. BUILT-IN TRANSISTOR KRA103M Q401 4822 130 42959 TRANSISTOR KTA1266(GR) Q682 9965 000 05643 TRANSISTOR 2SC2785(F) Q684 4822 130 42292 TRANSISTOR 2SC2120-Y(TPE2) Q685 9965 000 05643 TRANSISTOR 2SC2785(F) Q686...

- Page 72 ELECTRICAL PARTS LIST Pos. 12 NC Description R227 CHIP RES.(1608) 1/10W J 47 OHM R228 CHIP RES.(1608) 1/10W J 100K OHM R229 CHIP RES.(1608) 1/10W J 2.2K OHM R230 CHIP RES.(1608) 1/10W J 1.5K OHM R231 CHIP RES.(1608) 1/10W J 330K OHM R232 CHIP RES.(1608) 1/10W J 1K OHM R233...

- Page 73 ELECTRICAL PARTS LIST Pos. 12 NC Description R308 CHIP RES.(1608) 1/10W J 100 OHM R309 CHIP RES.(1608) 1/10W J 1.2K OHM R310 CHIP RES.(1608) 1/10W J 1K OHM R311 CARBON RES. 1/4W J 12 OHM R312 CHIP RES.(1608) 1/10W J 100 OHM R313 CHIP RES.(1608) 1/10W J 220K OHM R314...

- Page 74 ELECTRICAL PARTS LIST Pos. 12 NC Description R696 METAL OXIDE FILM RES. 1W J 2.2 OHM R697 CHIP RES.(1608) 1/10W J 10K OHM R698 CHIP RES.(1608) 1/10W J 8.2K OHM R701 CHIP RES.(1608) 1/10W J 75 OHM R702 CHIP RES.(1608) 1/10W J 3.3K OHM R703 CARBON RES.

- Page 75 ELECTRICAL PARTS LIST Pos. 12 NC Description R867 CHIP RES.(1608) 1/10W J 100 OHM R869 CHIP RES.(1608) 1/10W J 2.7K OHM R870 CHIP RES.(1608) 1/10W J 56K OHM R871 CHIP RES.(1608) 1/10W J 1M OHM R874 CHIP RES.(1608) 1/10W J 4.7K OHM R876 CHIP RES.(1608) 1/10W J 4.7K OHM R877...

- Page 76 ELECTRICAL PARTS LIST Pos. 12 NC Description POWER CBA Consists of the following H.V./POWER SUPPLY CBA CRT CBA H.V./POWER SUPPLY CBA COILS BC551 9965 000 13874 BEAD INDUCTORS FBA04HA600VB-00 BC602 9965 000 13875 BEAD INDUCTORS FBR07HA121TB-00 BC604 PCB JUMPER D0.6-P5.0 BC605 PCB JUMPER D0.6-P5.0 CAPACITORS...

- Page 77 ELECTRICAL PARTS LIST Pos. 12 NC Description D554 4822 130 32778 SWITCHING DIODE 1SS133(T-77) D556 4822 130 32778 SWITCHING DIODE 1SS133(T-77) D557 9965 000 13880 DIODE FR104-B D558 9965 000 13880 DIODE FR104-B D560 9965 000 13881 ZENER DIODE MTZJT-7736B D562 4822 130 32778 SWITCHING DIODE 1SS133(T-77) D563...

- Page 78 ELECTRICAL PARTS LIST Pos. 12 NC Description Q553 9965 000 13899 TRANSISTOR 2SC1627Y-TPE2 Q554 9965 000 05643 TRANSISTOR 2SC2785(F) Q602 9965 000 13901 MOS FET 2SK2647 Q603 4822 130 42292 TRANSISTOR 2SC2120-Y(TPE2) Q604 9965 000 05643 TRANSISTOR 2SC2785(F) Q605 4822 130 63665 TRANSISTOR 2SA950(O) Q606 4822 130 42292 TRANSISTOR 2SC2120-Y(TPE2) Q607...

- Page 79 ELECTRICAL PARTS LIST Pos. 12 NC Description R617 9965 000 18168 CEMENT RES. 5W K 0.56 OHM R618 PCB JUMPER D0.6-P5.0 R619 CARBON RES. 1/4W J 1.2K OHM R620 9965 000 24196 CARBON RES. 1/4W J 820K OHM R621 CARBON RES. 1/4W J 560K OHM R622 CARBON RES.

- Page 80 ELECTRICAL PARTS LIST Pos. 12 NC Description C503 CERAMIC CAP.(AX) B K 220PF/50V C504 CERAMIC CAP. B K 1000PF/2KV C505 ELECTROLYTIC CAP. 1UF/50V M H7 CONNECTORS CN501 9965 000 13911 PIN CONNECTOR 005P-5100 CN502 9965 000 05247 CONNECTOR BASE, 4P TUC-P04P-B1 JK501 9965 000 18173 CRT SOCKET ISHS40S COILS...

- Page 81 ELECTRICAL PARTS LIST Pos. 12 NC Description D907 4822 130 32778 SWITCHING DIODE 1SS133(T-77) D908 9965 000 18119 ZENER DIODE DZ-3.3BSBT265 D909 9965 000 18119 ZENER DIODE DZ-3.3BSBT265 IC’s IC901 9965 000 18141 IC:TEXT SAA5265 COILS L901 9965 000 18142 INDUCTOR 10UH-J-26T L902 9965 000 18142 INDUCTOR 10UH-J-26T TRANSISTORS...

-

Page 82: Exploded Views

CRT CBA Text CBA Sensor TB33 TB10 TB21 Junction A CBA Junction C CBA Main CBA TL14 Sensor CBA TL18 A1-5 H.V./Power Supply CBA A1-4 A1-9 A1-8 A1-7 A1-10 21PV385/07 TB23 A1-3 CL801 A1-13 SP151 A1-1 TB11 TL14 1-15-1 1-15-2 T6552CEX... - Page 83 Packing TAPE 1-15-3 T6552PEX...

-

Page 84: Mechanical Parts List

A1-5 A1-7 MECHANICAL PARTS LIST Pos. Pos. 12 NC Description Expl. View MECHANICAL PARTS LIST 0001 3143 027 60521 FRONT ASSY 21PV385/01/07/58 0001 3143 027 60531 FRONT ASSY 21PV385/39 0001 A1-1 FRONT CABINET 21" 0011 A1-3 WORDMARK SILVER 0005 A1-4 CASSETTE DOOR 21"... - Page 85 MECHANICAL PARTS LIST Pos. Pos. 12 NC Description Expl. View 0455 BAG (==>MAINS CORD) 0469 TOPFOIL 3143 023 20011 TEST TAPE FL6K(S) 3143 023 20021 TEST TAPE FL6NS8 3143 023 20051 TEST TAPE E-120 HS 3143 023 20041 TEST TAPE FL6M 1-16-2...

- Page 86 DECK MECHANISM SECTION TV-VCR COMBINATION Sec. 2: Deck Mechanism Section I Standard Maintenance I Mechanism Alignment Procedures I Disassembly / Assembly of Mechanism I Deck Exploded Views I Deck Parts List TABLE OF CONTENTS STANDARD MAINTENANCE ............. . 2-1-1 SERVICE FIXTURE AND TOOLS .

-

Page 87: Standard Maintenance

STANDARD MAINTENANCE Service Schedule of Components This maintenance chart shows you the standard of replacement and cleaning time for each part. Because those may replace depending on environment and purpose for use, use the chart for reference. H: Hours : Cleaning I: Replace Deck Periodic Service Schedule... - Page 88 Cleaning Cleaning of ACE Head Clean the head with a cotton swab. Cleaning of Video Head Procedure Clean the head with a head cleaning stick or chamois 1.Remove the top cabinet. cloth. 2.Dip the cotton swab in 90% isopropyl alcohol and Procedure clean the ACE Head.

-

Page 89: Service Fixture And Tools

SERVICE FIXTURE AND TOOLS J-1-1, J-1-2 Ref. No. Name Part No. Adjustment J-1-1 Alignment Tape 9965 000 14514 Head Adjustment of ACE Head J-1-2 Alignment Tape 9965 000 14516 Azimuth and X Value Adjustment of ACE Head / (2 Head model) Adjustment of Envelope Waveform 9965 000 14515 (4 Head model) -

Page 90: Mechanical Alignment Procedures

MECHANICAL ALIGNMENT PROCEDURES Explanation of alignment for the tape to correctly run B. Method to place the Cassette Holder in the tape- starts on the next page. Refer to the information below loaded position without a cassette tape on this page if a tape gets stuck, for example, in the 1. - Page 91 1. Tape Interchangeability Alignment Note: To do these alignment procedures, make sure that the Tracking Control Circuit is set to the preset position every time a tape is loaded or unloaded. (Refer to page 2-3-4, procedure 1-C, step 2.) Equipment required: Dual Trace Oscilloscope VHS Alignment Tape (9965 000 14516) Guide Roller Adj.

- Page 92 1-A. Preliminary/Final Checking and 4. If creasing or snaking is apparent, adjust the Tilt Alignment of Tape Path Adj. Screw of the ACE Head. (Fig. M6) Purpose: To make sure that the tape path is well stabilized. Azimuth Adj. Screw Symptom of Misalignment: If the tape path is unstable, the tape will be damaged.

- Page 93 5. To shift the CTL waveform, press CH UP or CH 5. When Guide Rollers [2] and [3] (Refer to Fig. M3) DOWN button on the remote control unit. Then are aligned properly, there is no envelope drop make sure that the maximum output position of PB either at the beginning or end of track as shown in ±...

- Page 94 1-D. Azimuth Alignment of Audio/Con- 2. When the tape has been curled up or bent, turn the trol/ Erase Head alignment screw to adjust the height of REV Post. (Refer to Fig. M11 and M13.) Purpose: To correct the Azimuth alignment so that the Audio/ Control/Erase Head meets tape tracks properly.

-

Page 95: Disassembly/Assembly Procedures Of Deck Mechanism

DISASSEMBLY/ASSEMBLY PROCEDURES OF DECK MECHANISM Before following the procedures described below, be sure to remove the deck assembly from the cabinet. (Refer to CABINET DISASSEMBLY INSTRUCTIONS on page 1-5-1 of Main Section.) All the following procedures, including those for adjustment and replacement of parts, should be done in Eject mode;... - Page 96 REMOVAL INSTALLATION STEP START- REMOVE/*UNHOOK/ /LOC. PART ADJUSTMENT Fig. No. UNLOCK/RELEASE/ CONDITION UNPLUG/DESOLDER Loading Arm (SP) (+)Refer to Alignment [32] [25] DM2, DM14 Assembly Sec.Page 2-5-1 Loading Arm (TU) (+)Refer to Alignment [32] [33] DM2, DM14 Assembly Sec.Page 2-5-1 [34] [2],[25] M Brake (TU) Assembly DM1, DM15 *(P-7), Brake Belt...

- Page 97 Top View [41] [42] [43] [46] [14] [13] [11] [15] [36] [10] [12] [35] [34] [40] [29] [30] [16] [39] [38] Fig. DM1 Bottom View [20] [33] [32] [24] [26] [27] [25] [23] [28] [22] [21] [31] Fig. DM2 2-4-3 Z13PDA...

- Page 98 (S-1) (S-1) (L-1) (L-3) (L-2) (S-1A) (P-1) Installation of [3] and [6] First, insert [6] diagonally in [3] as shown below. Then, install [6] in [3] while pushing (L-1) in a direction of arrow. After installing [6] in [3], confirm that pin A of [3] enters hole A of [6] properly.

- Page 99 [11] (S-4A) (L-4) [46] (P-3) [13] [47] Removal of [11] [12] (L-14) 1) Remove screw (S-4A). 2) Unhook spring (P-2). [10] Release (L-4) while (P-2) holding [12] with a finger. Loosen a finger holding [12] and remove [11]. (S-2) Pin of [12] Pin of [10] Groove of [28] When reassembling [10] and...

- Page 100 Installation of [13] and [12] (S-5) [14] (S-6) [16] [13] [15] Hook spring (P-3) up to [12] and [13], then install then to (P-3) the specified position so that [12] will be floated slightly while holding [12] and [13]. (Refer to Fig. A.) [12] Fig.

- Page 101 [22] (S-8) (C-2) (C-1) [23] (L-6) [21] (P-5) [20] Cap Belt (P-5) [28] Installation position of Cap Belt [21] Cap Belt When installing [23], install the spring (P-5) to [28] as shown in the left figure, and then install [23] while Pin on pressing the spring (P-5) to bottom...

- Page 102 (P-6) [25] (C-4) [31] Refer to the Alignment Section, Page 2-5-1. (S-9) [29] [33] [30] (L-11) (L-10) [32] (L-8) (C-3) [27] [28] [24] [26] (L-9) Fig. DM14 Fig. DM13-1 [36] Break belt Installation of [25] (P-7) [34] Position of Mode Lever when installed [40] Pin of [35] Pin of [31]...

- Page 103 [42] [41] [43] (L-13) Fig. DM16 (P-9) [44] [45] Slide Fig. DM17 2-4-9 Z13PDA...

-

Page 104: Alignment Procedures Of Mechanism

ALIGNMENT PROCEDURES OF MECHANISM The following procedures describe how to align the Alignment 1 individual gears and levers that make up the tape load- Loading Arm (SP) and (TU) Assembly ing/unloading mechanism. Since information about the state of the mechanism is provided to the System Install Loading Arm (SP) and (TU) Assembly so Control Circuit only through the Mode Switch, it is that their triangle marks point to each other as... -

Page 105: Deck Exploded Views

DECK EXPLODED VIEWS Deck Mechanism View 1 Mark Description Floil G-684G or Multemp MH-D (Blue grease) SLIDUS OIL #150 B494 L1467 L1191 B553 B411 B567 L1053 B410 L1051 Chassis Assembly Top View (Lubricating Point) B501 B560 L1450 L1450 B426 L1466 B121 B126 B492... - Page 106 Deck Mechanism View 2 Mark Description Floil G-684G or Multemp MH-D (Blue grease) B587 B521 B487 SLIDUS OIL #150 B416 B591 SANKOUL FG84M (Yellow grease) B520 B590 B522 L1406 B148 B499 B508 B592 B573 B574 B558 B564 B557 B414 B565 B525 L1151 B417...

- Page 107 Deck Mechanism View 3 Mark Description Floil G-684G or Multemp MH-D (Blue grease) L1321 SLIDUS OIL #150 B347 L1321 B355 B354 B483 L1341 B425 B482 B562 B300 B563 B313 L1474 B529 B360 B359 B361 B555 B561 B303 Some Ref. Numbers are not in sequence. B514 2-6-3 Z13P2HDEX...

-

Page 108: Deck Parts List

DECK PARTS LIST DECK PARTS LIST Pos. 12 NC Description Pos. 12 NC Description 9965 000 23417 CYLINDER ASS. B522 9965 000 12373 TG POST ASS. 9965 000 17217 LOADING MOTOR ASS. B525 9965 000 12230 LDG BELT 9965 000 17191 PULLEY ASS. B529 9965 000 08504 CLEANER ASS.

Need help?

Do you have a question about the 21PV385 and is the answer not in the manual?

Questions and answers