Mitsubishi Electric PMFY-P06NBMU-E Technical & Service Manual

Ceiling cassettes

Hide thumbs

Also See for PMFY-P06NBMU-E:

- Technical & service manual (36 pages) ,

- Installation manual (44 pages) ,

- Manual (37 pages)

Table of Contents

Advertisement

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

Indoor unit

[Model names]

[Service Ref.]

PMFY-P06NBMU-E

PMFY-P06NBMU-E

PMFY-P06NBMU-E#2

PMFY-P06NBMU-ER4

PMFY-P08NBMU-E

PMFY-P08NBMU-E

PMFY-P08NBMU-E#2

PMFY-P08NBMU-ER4

PMFY-P12NBMU-E

PMFY-P12NBMU-E

PMFY-P12NBMU-E#2

PMFY-P12NBMU-ER4

PMFY-P15NBMU-E

PMFY-P15NBMU-E

PMFY-P15NBMU-E#2

PMFY-P15NBMU-ER4

INDOOR UNIT

R410A / R22

PMFY-P06NBMU-E

PMFY-P06NBMU-ER3

PMFY-P06NBMU-ER5

PMFY-P08NBMU-E

PMFY-P08NBMU-ER3

PMFY-P08NBMU-ER5

PMFY-P12NBMU-E

PMFY-P12NBMU-ER3

PMFY-P12NBMU-ER5

PMFY-P15NBMU-E

PMFY-P15NBMU-ER3

PMFY-P15NBMU-ER5

CONTENTS

1. TECHNICAL CHANGES ....................... 2

2. FEATURES ........................................... 3

3. PART NAMES AND FUNCTIONS ........ 3

4. SPECIFICATION ................................... 5

5. OUTLINES AND DIMENSIONS ............ 9

6. WIRING DIAGRAM ............................. 10

7. REFRIGERANT SYSTEM DIAGRAM .... 14

8. MICROPROCESSOR CONTROL ....... 15

9. TROUBLESHOOTING ........................ 22

10. DISASSEMBLY PROCEDURE ........... 31

11. RoHS PARTS LIST ............................. 35

April 2012

No. OC341

REVISED EDITION-F

1

Revision:

• PMFY-P06/08/12/15NBMU-

ER5 have been added in

REVISED EDITION-F.

• Some descriptions have

been modified.

1

• Please void OC341

REVISED EDITION-E.

NOTE:

1

• This manual describes

only service data of the

indoor units.

• RoHS compliant products

have <G> mark on the

1

spec name plate.

• For servicing RoHS compli-

ant products, refer to the

RoHS PARTS LIST.

Advertisement

Table of Contents

Summary of Contents for Mitsubishi Electric PMFY-P06NBMU-E

-

Page 1: Table Of Contents

SPLIT-TYPE, HEAT PUMP AIR CONDITIONERS April 2012 No. OC341 REVISED EDITION-F TECHNICAL & SERVICE MANUAL R410A / R22 Indoor unit [Model names] [Service Ref.] PMFY-P06NBMU-E PMFY-P06NBMU-E PMFY-P06NBMU-E Revision: • PMFY-P06/08/12/15NBMU- PMFY-P06NBMU-E#2 PMFY-P06NBMU-ER3 ER5 have been added in REVISED EDITION-F. PMFY-P06NBMU-ER4 PMFY-P06NBMU-ER5 •... -

Page 2: Technical Changes

PMFY-P08NBMU-ER3 PMFY-P08NBMU-ER4 → PMFY-P12NBMU-ER3 PMFY-P12NBMU-ER4 → PMFY-P15NBMU-ER3 PMFY-P15NBMU-ER4 1. DRAIN PIPE has been changed. 2. JOINT SOCKET (FOR DRAIN PIPE) has been added. → PMFY-P06NBMU-E#2 PMFY-P06NBMU-ER3 → PMFY-P08NBMU-E#2 PMFY-P08NBMU-ER3 → PMFY-P12NBMU-E#2 PMFY-P12NBMU-ER3 → PMFY-P15NBMU-E#2 PMFY-P15NBMU-ER3 • CONTROLLER BOARD (I.B) has been changed. (It is possible to extract a signal for an external heater.) →... -

Page 3: Features

FEATURES Indoor Unit Models Cooling capacity / Heating capacity PMFY-P06NBMU-E 6,000 / 6,700 Btu/h PMFY-P08NBMU-E 8,000 / 9,000 Btu/h PMFY-P12NBMU-E 12,000 / 13,500 Btu/h PMFY-P15NBMU-E 15,000 / 17,000 Btu/h 1. Fresh Air Intake Air recycled indefinitely can become stale and stagnant with air quality suffering significantly. Fresh air is the answer and it is for this reason that the PMFY- series takes in air directly from outdoors. -

Page 4: Wired Remote Controller

Wired remote controller Once the controllers are set, the same operation mode can be repeated by simply pressing the ON/OFF button. Note: The phrase "Wired remote controller" in this manual refers only to the PAR-21MAA. If you need any information for the other remote controller, please refer to either the installation manual or initial setting manual which are included in remote controller's box. -

Page 5: Specification

SPECIFICATION 4-1. SPECIFICATIONS PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E Service ref. PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P12NBMU-E#2 PMFY-P15NBMU-E#2 PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P15NBMU-ER3 Item PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P12NBMU-ER4 PMFY-P15NBMU-ER4 PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P12NBMU-ER5 PMFY-P15NBMU-ER5 Power V · H Single phase 208-230V 60Hz Cooling capacity... - Page 6 4-2. ELECTRICAL PARTS SPECIFICATIONS PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P15NBMU-E PMFY-P12NBMU-E Service Ref. PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P15NBMU-E PMFY-P12NBMU-E PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P15NBMU-E#2 PMFY-P12NBMU-E#2 Symbol PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P15NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P15NBMU-ER4 PMFY-P12NBMU-ER4 Parts name PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P15NBMU-ER5 PMFY-P12NBMU-ER5 Room temperature TH21 Resistance 30°F/15.8kΩ, 50°F/9.6kΩ, 70°F/6.0kΩ, 80°F/4.8kΩ, 90°F/3.9kΩ, 100°F/3.2kΩ...

- Page 7 4-Ø1/8 Fresh air intake hole Fresh air intake hole (Unit: inch) (Knockout) (Knockout) Service Ref. Air fl ow (Hi) Air capacity taken from outside 300 CFM 60CFM PMFY-P06NBMU-E/E /E#2/ER3/ER4/ER5 PMFY-P08NBMU-E/E /E#2/ER3/ER4/ER5 320 CFM 64CFM 320CFM 64CFM PMFY-P12NBMU-E/E /E#2/ER3/ER4/ER5 370CFM 74CFM...

-

Page 8: Noise Criterion Curves

4-4. NOISE CRITERION CURVES PMFY-P06NBMU-E PMFY-P08/12NBMU-E PMFY-P06NBMU-E PMFY-P08/12NBMU-E SPL(dB) LINE NOTCH SPL(dB) LINE NOTCH PMFY-P06NBMU-E#2 PMFY-P08/12NBMU-E#2 High High PMFY-P06NBMU-ER3 PMFY-P08/12NBMU-ER3 Medium1 Medium1 Medium2 Medium2 PMFY-P06NBMU-ER4 PMFY-P08/12NBMU-ER4 PMFY-P06NBMU-ER5 PMFY-P08/12NBMU-ER5 NC-70 NC-70 NC-60 NC-60 NC-50 NC-50 NC-40 NC-40 NC-30 NC-30 APPROXIMATE THRESHOLD OF... -

Page 9: Outlines And Dimensions

OUTLINES AND DIMENSIONS PMFY-P06NBMU-E/E /E#2/ER3/ER4/ER5 Unit : inch (mm) PMFY-P08NBMU-E/E /E#2/ER3/ER4/ER5 PMFY-P12NBMU-E/E /E#2/ER3/ER4/ER5 PMFY-P15NBMU-E/E /E#2/ER3/ER4/ER5 OC341F... -

Page 10: Wiring Diagram

WIRING DIAGRAM PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E OC341F... - Page 11 PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E OC341F...

- Page 12 PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P12NBMU-E#2 PMFY-P15NBMU-E#2 PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P15NBMU-ER3 PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P12NBMU-ER4 PMFY-P15NBMU-ER4 OC341F...

- Page 13 PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P12NBMU-ER5 PMFY-P15NBMU-ER5 OC341F...

-

Page 14: Refrigerant System Diagram

REFRIGERANT SYSTEM DIAGRAM PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P12NBMU-E#2 PMFY-P15NBMU-E#2 PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P15NBMU-ER3 PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P12NBMU-ER4 PMFY-P15NBMU-ER4 PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P12NBMU-ER5 PMFY-P15NBMU-ER5 Thermistor TH23 Strainer (#100mesh) <Gas pipe temperature detection> Gas pipe Thermistor TH22 <Liquid pipe temperature detection>... -

Page 15: Microprocessor Control

MICROPROCESSOR CONTROL INDOOR UNIT CONTROL 8-1. COOL OPERATION <How to operate> 1 Press POWER ON/OFF button. TIME SUN MON TUE WED THU FRI SAT TIMER AFTER AFTER 2 Press the operation MODE button to display COOL. ERROR CODE FUNCTION û Fû C FILTER û... - Page 16 Control modes Remarks Control details 3. Drain pump 3-1. Drain pump control • Always drain pump ON during the COOL and DRY mode operation. (Regardless of the thermostat ON/OFF) • When the operation mode is changed from COOL or DRY to any other mode (including Stop), the drain pump continues to run for 3 minutes.

-

Page 17: Dry Operation

8-2. DRY OPERATION <How to operate> 1 Press POWER ON/OFF button. TIME SUN MON TUE WED THU FRI SAT TIMER AFTER AFTER 2 Press the operation MODE button to display DRY. ERROR CODE FUNCTION û Fû C FILTER û Fû C 3 Press the TEMP. -

Page 18: Fan Operation

8-3. FAN OPERATION <How to operate> 1 Press POWER ON/OFF button. TIME SUN MON TUE WED THU FRI SAT 2 Press the operation MODE button to display FAN. TIMER AFTER AFTER ERROR CODE FUNCTION û Fû C FILTER û Fû C WEEKLY SIMPLE ONLY1Hr. -

Page 19: Heat Operation

8-4. HEAT OPERATION <How to operate> 1 Press POWER ON/OFF button. 2 Press the operation MODE button to display HEAT. TIME SUN MON TUE WED THU FRI SAT 3 Press the TEMP. button to set the desired temperature. TIMER AFTER AFTER ERROR CODE FUNCTION... - Page 20 From the preceding page Control modes Control details Remarks 2-3. Thermo OFF mode 2. Fan When the thermostat function changes to OFF, the indoor fan operates in [Extra low]. 2-4. Heat defrosting mode The indoor fan stops. 3. Drain pump No drain pump operation However, when the control changes from COOL or DRY operation, the drain pump operates for 3 minutes.

- Page 21 8-5. AUTO OPERATION [AUTOMATIC COOL/HEAT CHANGE OVER OPERATION] <How to operate> 1 Press POWER ON/OFF button. TIME SUN MON TUE WED THU FRI SAT 2 Press the operation MODE button to display AUTO. TIMER AFTER AFTER ERROR CODE FUNCTION 3 Press the TEMP. button to set the desired temperature. û...

-

Page 22: Troubleshooting

TROUBLESHOOTING 9-1. HOW TO CHECK THE PARTS PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P12NBMU-E#2 PMFY-P15NBMU-E#2 PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P15NBMU-ER3 PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P12NBMU-ER4 PMFY-P15NBMU-ER4 PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P12NBMU-ER5 PMFY-P15NBMU-ER5 Parts name Check points Thermistor (TH21) Disconnect the connector then measure the resistance with a tester. -

Page 23: Linear Expansion Valve

< Thermistor for lower temperature > <Thermistor characteristic graph> Thermistor for Thermistor <Room temperature detection> (TH21) lower temperature Thermistor <Liquid pipe temperature detection> (TH22) Thermistor <Gas pipe temperature detection> (TH23) Thermistor R =15k' ± 3% Fixed number of B=3480 ± 2% Rt=15exp { 3480( 273+(t-32)/1.8 30_F... - Page 24 <Output pulse signal and the valve operation> Output Output (Phase) Closing a valve : 1 → 2 → 3 → 4 → 1 Opening a valve : 4 → 3 → 2 → 1 → 4 The output pulse shifts in above order. •...

- Page 25 9-2. FAN MOTOR CHECK Check method of indoor fan motor (fan motor/controller board) Notes · High voltage is applied to the connecter (FAN)(CNMF1, 2) for the fan motor. Pay attention to the service. · Do not pull out the connector (FAN)(CNMF1, 2) for the motor with the power supply on, doing so may result in damage to the board.

-

Page 26: Function Of Dip Switch

Power ON/OFF by breaker Effective Not effective Indoor controller board MODELS SW 2 MODELS SW 2 Before PMFY-P12NBMU-E PMFY-P06NBMU-E power Capacity 1 2 3 4 5 6 1 2 3 4 5 6 <Initial setting> supply code setting Set for each capacity. - Page 27 Effective Switch Pole Operation by switch Remarks timing SW11 Address board 1s digit How to set addresses address SW12 SW11 <Initial setting> Example : If address is “3”, remain SW12 setting SW12 SW11 (for over 10) at “0”, and match SW11 (for 1 to 9) SW12 with “3”.

- Page 28 9-4. TEST POINT DIAGRAM 9-4-1. Indoor controller board PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E CN32 Connector Function setting (Remote switch) Model selection Capacity setting CN27 Connector (Damper) 12VDC (1 : +) CN6V Vane motor output (MV) 12VDC pulse output...

- Page 29 Indoor controller board PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P12NBMU-E#2 PMFY-P15NBMU-E#2 PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P15NBMU-ER3 PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P12NBMU-ER4 PMFY-P15NBMU-ER4 PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P12NBMU-ER5 PMFY-P15NBMU-ER5 Power supply Drain pump output (DP) 1-2 : 208-230V AC 1-3 : 208-230V AC FUSE 6.3A 250V CNMF1, CNMF2 FAN motor...

- Page 30 9-4-2. Address board PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P12NBMU-E#2 PMFY-P15NBMU-E#2 PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P15NBMU-ER3 PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P12NBMU-ER4 PMFY-P15NBMU-ER4 PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P12NBMU-ER5 PMFY-P15NBMU-ER5 Voltage selector Function setting SW12 SW11 SW14 Address setting Address setting Branch No.

-

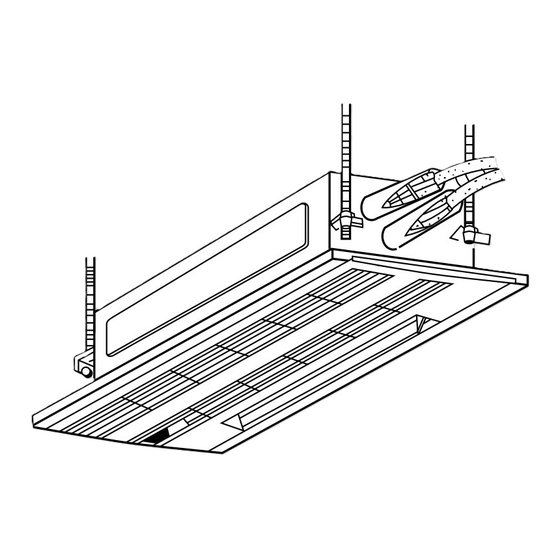

Page 31: Disassembly Procedure

DISASSEMBLY PROCEDURE PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P12NBMU-E#2 PMFY-P15NBMU-E#2 PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P15NBMU-ER3 PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P12NBMU-ER4 PMFY-P15NBMU-ER4 PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P12NBMU-ER5 PMFY-P15NBMU-ER5 Be careful when removing heavy parts. OPERATING PROCEDURE PHOTOS & ILLUSTRATIONS Air intake grille Photo 1 1. - Page 32 OPERATING PROCEDURE PHOTOS & ILLUSTRATIONS Figure 6 Hooks Removing the grille (1) Open the intake grille by pressing of the air intake PUSH grille and remove the air fi lter (× 2). (See Figure 1) (2) Remove the screw cover in the middle of the air outlet. (See Figure 7) (3) Open the upper and lower fl...

- Page 33 OPERATING PROCEDURE PHOTOS & ILLUSTRATIONS Photo 2 Claw in middle 2. Removing the electrical parts box Nozzle Electrical parts of nozzle (1) Remove the panel. (2) Remove the address board cover. (3) Remove the electrical parts cover. (4) Disconnect the connectors of fan motor, vane motor, drain pump, room temperature thermistor, pipe temperature thermistor (Liquid.

- Page 34 OPERATING PROCEDURE PHOTOS & ILLUSTRATIONS Photo 6 5. Removing the drain pump (1) Remove the panel. (2) Unhook the claw in the middle of nozzle and remove the Drain sensor drain pan. (See Photo 2) (3) Remove the address board cover. (See Photo 3) Drain pump (4) Remove the electrical parts cover.

-

Page 35: Rohs Parts List

RoHS PARTS LIST PANEL PARTS PMP-16BMU (FOR PMFY-P06/08/12/15NBMU-E PMFY-P06/08/12/15NBMU-E • PMP-16BMUW (FOR PMFY-P06/08/12/15NBMU-E#2 PMFY-P06/08/12/15NBMU-ER3 • • PMFY-P06/08/12/15NBMU-ER4 PMFY-P06/08/12/15NBMU-ER5) • Q'ty/set Wiring Recom- Remarks Part No. Part Name Specifi cation Diagram mended PMP-16 (Drawing No.) Symbol Q'ty BMUW T7W E16 003 AIR OUTLET GRILLE T7W E22 003 AIR OUTLET GRILLE... - Page 36 RoHS PARTS LIST FUNCTIONAL PARTS PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E OC341F...

- Page 37 RoHS PARTS LIST Part number that is circled is not shown in the figure. Q'ty/set Wiring Recom- Remarks PMFY- Part No. Part Name Specification Diagram mended (Drawing No.) P·NBMU-E P·NBMU-E Symbol Q'ty 06/08 12/15 06/08 12/15 BEARING MOUNT SLEEVE BEARING LINE FLOW FAN STABILIZER ASSY VANE MOTOR...

- Page 38 RoHS PARTS LIST FUNCTIONAL PARTS PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P12NBMU-E#2 PMFY-P15NBMU-E#2 PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P15NBMU-ER3 PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P12NBMU-ER4 PMFY-P15NBMU-ER4 PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P12NBMU-ER5 PMFY-P15NBMU-ER5 OC341F...

- Page 39 RoHS PARTS LIST Part number that is circled is not shown in the figure. Q'ty/set PMFY-P· Wiring Recom- Remarks Part No. Part Name Specifi cation Diagram mended NBMU-E#2 NBMU-ER4 (Drawing No.) Symbol Q'ty NBMU-ER3 NBMU-ER5 06/08 12/15 06/08 12/15 R01 23A 102 BEARING MOUNT R01 E04 103 SLEEVING BEARING...

- Page 40 RoHS PARTS LIST ELECTRICAL PARTS PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E PMFY-P08NBMU-E PMFY-P12NBMU-E PMFY-P15NBMU-E PMFY-P06NBMU-E#2 PMFY-P08NBMU-E#2 PMFY-P12NBMU-E#2 PMFY-P15NBMU-E#2 PMFY-P06NBMU-ER3 PMFY-P08NBMU-ER3 PMFY-P12NBMU-ER3 PMFY-P15NBMU-ER3 PMFY-P06NBMU-ER4 PMFY-P08NBMU-ER4 PMFY-P12NBMU-ER4 PMFY-P15NBMU-ER4 PMFY-P06NBMU-ER5 PMFY-P08NBMU-ER5 PMFY-P12NBMU-ER5 PMFY-P15NBMU-ER5 Q'ty/set Remarks Wiring Recom- PMFY-P06/08/12/15 Part No. Part No. Specifi cation...

- Page 41 OC341F...

- Page 42 HEAD OFFICE : TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO100-8310, JAPAN cCopyright 2005 MITSUBISHI ELECTRIC CORPORATION Distributed in Apr. 2012 No. OC341 REVISED EDITION-F Distributed in Dec. 2009 No. OC341 REVISED EDITION-E PDF 7 Distributed in Dec. 2008 No. OC341 REVISED EDITION-D PDF 7 Distributed in May 2008 No.

Need help?

Do you have a question about the PMFY-P06NBMU-E and is the answer not in the manual?

Questions and answers